What is Direct to Film (DTF) Printing and How it Works

DTF printing, which stands for Direct to Film, is a printing technique that consists of direct colour printing on a film that is then transferred onto any type of fabric.

The DTF printing process consists of three main steps:

- Printing the design onto the film: a DTF printer is used to print the desired design onto a PET film. The film is usually about 0.75 mm thick and is loaded into the printer so that the surface to be printed on faces upwards. The printer uses water-based inks, with white being added to ensure good background coverage.

- Application of glue powder: the printed film is then passed through a tray in which a special glue powder is applied. The glue consists of a thermoplastic polymer that melts when heated and creates a permanent bond between the print and the fabric.

- Transfer of the print onto the fabric: the film with the glue powder is then transferred onto the fabric to be printed. The fabric is placed on a heated plate and the film is applied with a press. The heat of the plate melts the glue, which sticks to the fabric and transfers the print.

Advantages and Disadvantages of Direct to Film (DTF) Printing

DTF printing is a versatile and reliable printing technique that can be used to produce a variety of customised products, including t-shirts, sweatshirts, caps, bags and gadgets.

Here are some of the advantages of DTF printing

- Broad fabric compatibility: DTF printing can be used on a wide range of fabrics, including cotton, polyester, silk, leather and terry.

- Wash resistance: DTF printing is resistant to washing up to 60 degrees Celsius.

- High print quality: DTF printing offers good print quality, with bright colours and accurate details.

Here are some of the disadvantages of DTF printing:

- Production time: DTF printing takes longer than DTG printing. This is because the DTF printing process requires more steps, including printing the design onto the film, applying the glue powder and transferring the print onto the fabric.

- Wash resistance: DTF printing is not completely resistant to washing, especially on light-coloured fabrics. The glue powder may fade or peel off after many washes.

- Finish: DTF print has a slightly rough finish, which can be felt to the touch. This finish is due to the DTF film, which is applied to the fabric during the printing process.

DTF printing is a good choice for those who want to print on a wide range of fabrics with good print quality and wash resistance.

Some examples of Direct To Film printing on various fabrics:

ORIGINAL FILE PRINT ON T-SHIRT PRINT ON T-SHIRT

TRANSPARENT BACKGROUND 100% COTTON BLACK 100% COTTON WHITE

How can I know if that product is printable in DTF and how do I set up DTF printing ?

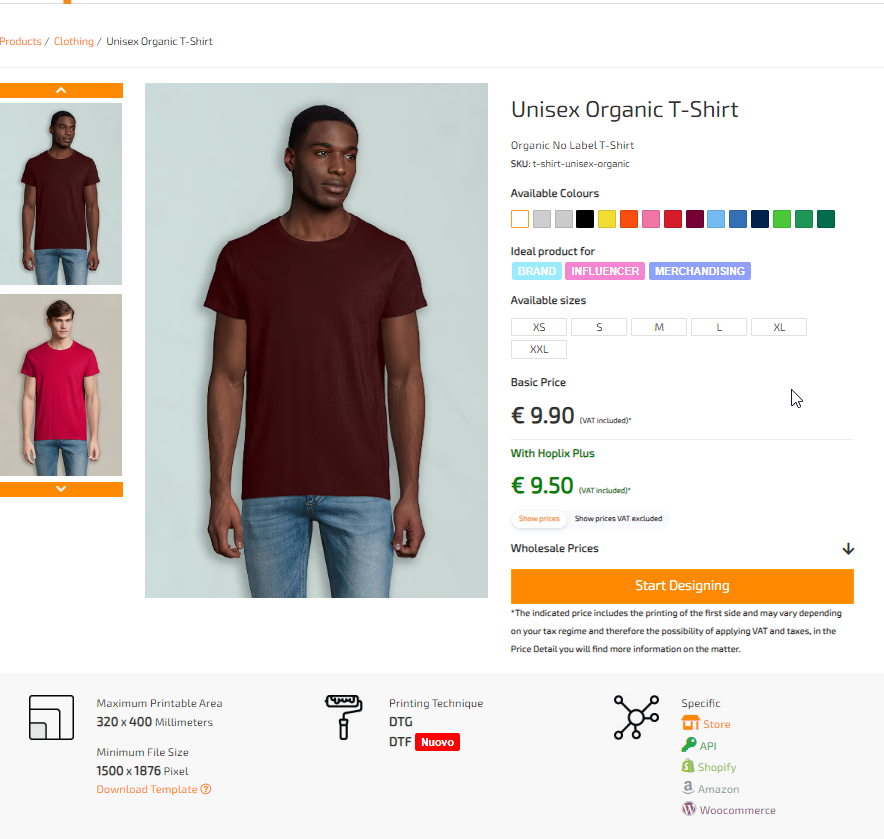

In the detail of each product sheet you will find an indication of the printing technique

Once the product has been created in your private area in the My Products Page > Select the Product > Actions > Edit and in the Products tab for products where DTF printing is available you can indicate that that product must be DTF printed, once set it will no longer be possible to modify the printing technique and every time that product is ordered it is made with the indicated printing technique.

The range of products printed in DTF is constantly updated, please let us know at [email protected] the products you would like to print in DTF.